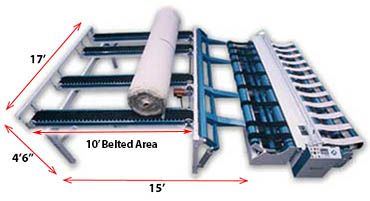

Accu-Cut J-2

Features

- One person can unroll, inspect, measure, cut, reverse roll and wrap all your carpet and vinyl simply and accurately.

- The J-2’s steel frame incorporates laser cut precision and is welded, not bolted, providing you with the strongest and most durable machine frame available.

- PLC control includes multiple preset cut storage and product settings. Foot and inch counter automatically slows down the machine then stops precisely at the programmed measurement.

- We have designed an affordable cut and roll machine that is very reliable and extremely simple to operate.

- The J-2 takes up little space and is simple to move on its industrial strength casters. Lifting brakes keep the machine stationary while in use.

- Wrap around foot cable control provides the operator with a way to engage the rollers from the front or side of the machine. Makes wrapping and taping rolls simple.

Specifications

- POWER: 220 volts – single phase / 60 hertz / 15 amps

- BLADES: Standard, slotted double edge carpet blade

- SIZE: 14′ 8″ long x 5′ 6″ wide x 3′ 3″ high (4.47m long x 1.68m wide x .99m high)

- LIMITED WARRANTY: 1 year parts and labor, 3 years on frame

Meets all UL and CSA safety standards.